Introduction

HP Jet Fusion technology is redefining the boundaries of digital manufacturing with its ability to produce complex and intricate designs. This article explores various innovative design concepts that HP Jet Fusion makes possible, demonstrating the technology’s versatility and creative potential.

Design for Interlocking Parts:

HP Jet Fusion allows for the creation of interlocking parts, like chains and chainmail, in a single print. This capability eliminates the need for assembly post-printing, offering efficiency and design complexity that traditional manufacturing methods cannot match.

- Chains: Chains can be printed with their links interlocked, requiring sufficient gaps to avoid fusing. Design modifications can include different shapes, textures, or even reconfigurable links.

- Chainmail: Chainmail designs can be produced in large sheets, suitable for applications requiring flexible, textile-like structures.

Innovative Fabric Designs:

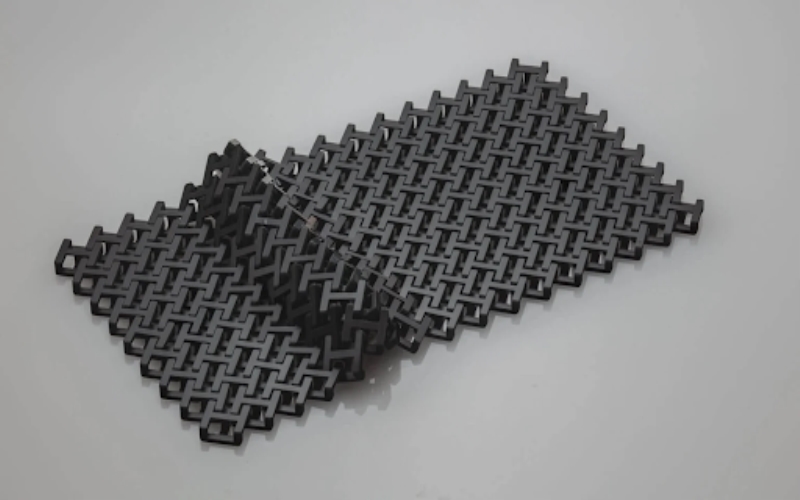

HP Jet Fusion enables the creation of unique fabric-like structures, inspired by traditional metal fabrics but realized in plastic. This includes quad-based and hexagon-based fabrics, which can be used to create intricate and flexible designs.

- Quad-Based Fabric: Comprises rings connected by platform units, allowing for scalability and variation in design.

- Hexagon-Based Fabric: Offers a different kind of draping, with hexagons connected by posts and linked with triangles, creating a fabric with no “wrong” side.

Single Link Mesh and Weaves:

The technology allows for the simplification of forms, such as single link meshes and intricate weaves, facilitating the creation of unique mesh-like structures.

- Single Link Mesh: Utilizes angled rings to create a continuous, interlocking design.

- Weave Chainmail: More complex weaves like six-in-one can be created, which are more resistant to folding and offer a stiffer structure.

Living Hinges and Flexible Designs:

HP Jet Fusion is capable of printing finitely flexible parts, such as living hinges. This allows for the creation of collapsible and expandable structures, suitable for various applications.

Design for Sound:

The technology also enables the design of parts with specific acoustic properties. This can include parts that generate sound through movement or resonance, providing opportunities for innovative musical instrument design.

Case Study: 3D Printed Skirt:

A practical application of HP Jet Fusion’s capabilities is demonstrated in a 3D printed skirt, designed for Coachella. The skirt uses a quad-based mesh structure, providing durability and comfort, and showcases the potential for fashion-forward applications.

Conclusion

HP Jet Fusion technology opens up a world of possibilities for designers and manufacturers. From creating complex interlocking parts to flexible fabrics and innovative acoustic designs, this technology provides the tools to push the limits of creativity and functionality in digital manufacturing.