Your crankshaft sensor sends information to the engine’s control unit about the position and rotational speed of your engine. This data is used to regulate fuel injection and ignition timing. A defective crankshaft sensor can cause your vehicle to fail to start. It can also affect your vehicle’s idling, acceleration, and gas mileage.

Crankshaft Position Sensor

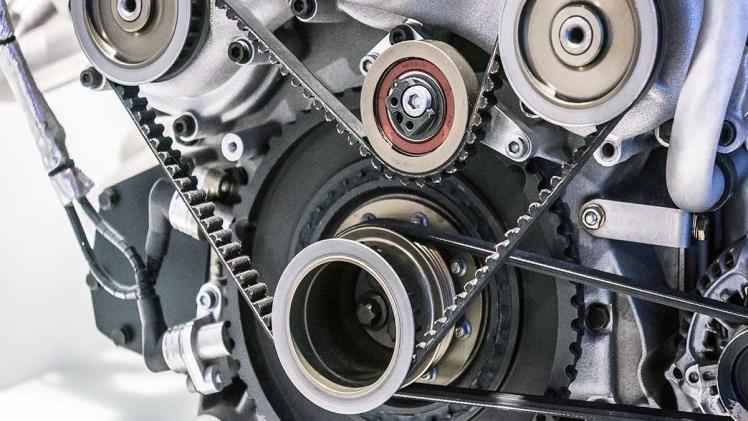

The crankshaft position sensor (also known as the CKP sensor or CPS) monitors the position and rotational speed of your engine’s crankshaft and sends it to the onboard computer, which controls fuel injection and ignition timing. This information allows the onboard computer to regulate these important systems so they work perfectly together for efficient, smooth engine performance. A crankshaft position sensor failure can lead to problems like stalling and an illuminated check engine light. Crankshaft sensor use a toothed disc mounted on the shaft with a stationary detector and electronic circuitry (Fig-1).

Get it today and make sure you’re driving your car at its best every time you get behind the wheel. The crankshaft position sensor works by generating an electrical voltage based on fluctuations in the magnetic field. This voltage is ampliphied by a transistor and sent to the engine control unit.

Crankshaft Speed Sensor

Crankshaft speed sensors monitor the rotational speed of the crankshaft in petrol and diesel engines. This information is used by the engine control unit (ECU) to control fuel injection and ignition timing. Most crankshaft position sensors are Hall effect sensors. They consist of a sensor magnet and a wire wound around the magnet and a toothed wheel. The toothed wheel disrupts the magnetic field and causes an induced circuit voltage.

The magnetic field disturbance and the induced voltage are greatest when either the gap centres or the tooth leading and trailing edges align with the sensor. This results in a pulsed voltage signal that is sent to the ECU for processing. Before testing a crankshaft position sensor, remove the plug connection and check the internal resistance with an ohmmeter. If the reading is higher than 200 to 1,000 ohms, there is likely a short circuit in the coil.

Crankshaft Angle Sensor

The crankshaft angle sensor measures the position and rotational speed of the crankshaft. It provides this information to the engine control system and helps keep your vehicle running at optimal performance levels. In most modern ICE engines, the crankshaft position sensor controls ignition and engine management. Without the signal sent by this sensor, the computer has no way of knowing when to fire the spark plug and trigger the fuel injectors.

When the disc spins, the teeth or marks pass by the sensor, generating electrical pulses that are converted to the corresponding shaft rotational speed. The sensor is positioned near the steel-toothed ring (4) of the crankshaft, and it also interacts with magnets mounted on the ring. The magnetic permeability of the steel-toothed ring determines one marker type, while a special label on the interval between the teeth determines the start count.

Camshaft Position Sensor

The camshaft position sensor helps keep the engine running in harmony by monitoring the position of the camshaft and reporting that data to your vehicle’s onboard computer system. This helps the computer control system regulate fuel injection and spark timing. Fortunately, Suncent auto parts offers a high-quality crankshaft position sensor that’s designed to be robust and reliable.

Modern engines are complex machines with many different components that interact in precise ways to ensure that your engine runs properly and safely. A faulty component can throw off this entire process, leaving your engine ineffective and potentially unsafe to drive.

More Words

The camshaft position sensor is one of the more common types of sensors in a modern automotive engine, and it typically works by sending voltage signals to the electronic control module (ECM) via a magnetic circuit. The ECM uses the information from this sensor to determine when air, fuel and spark are available in the right combination for efficient combustion and to optimize fuel economy and emissions.