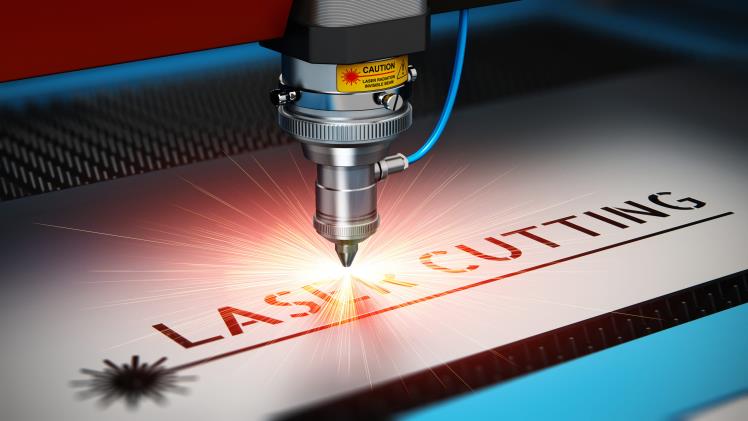

Welding operations use the latest technology to ensure quality welds. Welders must consider the working procedure and handling of all types of welding machines. They must have complete knowledge about using the latest welding equipment to provide exact results. Laser-cutting machines now replace the traditional welding procedures. This method is beneficial for creating effective results that meet the requirements of every welding project. The welding procedure can be easier with distributors like Lincoln Electric distributors in UAE, which ensures equality of welds for your materials. This article has complete guidance about selecting the right material for performing laser-cutting procedures.

Understanding the basics

Every welder must have complete knowledge of different metal types. In the case of laser cutting technology, every laser beam is directly related to the type of metal. laser cutting machine Dubai use a specific beam of light, which is used to perform complex types of metal cuts. This is the best way to get quality results. They must educate themself about using laser machines and suitable materials for performing efficient laser operations.

Focusing on thickness

Before starting the welding process, it is important to consider the thickness of the metal piece. The laser cutting machine is constructed to hold the metal piece effectively for performing laser operation. The thickness of metal plays an important role in deciding its welding quality. Laser machines have different capacities to work on materials with different thickness ranges. It can be made easy by placing the exact material in the laser welding machine that matches to its cutting capacity. If metal pieces have greater thickness, then use manual ways to make it adjustable with the capacity of the cutting machine.

Material quality

One of the main factors that affect the welding process is the quality of the material. Always make sure to use high-quality material to put in the welding machine. When you are performing the laser cutting operation on low-quality material then, you can get uneven cuts, which can also damage the excessive part of the metal. These poor-quality materials can also affect the efficiency of welding machines and can create harmful effects for welders. That’s why it is very important to identify the quality of the material before starting the welding procedure.

Temperature maintenance

There is a considerable possibility of thermal reaction in the welding procedure. Welders must have complete knowledge about managing the thermal effects of the laser cutting process. It is very important to adjust the thermal condition of the equipment before starting it. When the equipment is ready for welding at a specific temperature, then the material is placed to perform an effective laser cut.

Conclusion

This information is very helpful for them to select the right metal part for its proper functioning. Different types of heavy industries require precise welding results for accurate working. There are several factors that affect selecting the right material for laser cutting. As a professional welder, you must understand the quality of metal pieces and the working conditions of your equipment. All these things are very important for performing better results according to your preferences.