When talking about logistics and supply chain management, the terms fulfillment center and warehouse are often used interchangeably, but their meanings can vary depending on the context.

For instance, both Shopify and traditional brick-and-mortar shops are, at their core, large warehouses where businesses can keep the physical goods they sell in stock for their customers.

Despite this similarity, there can be significant variation in both the services offered and how they are utilized. To help you determine which solution is best suited to your specific business requirements, this guide will explain how each one works.

In order to save money, most businesses store their inventory in a warehouse and hire fulfillment warehouse services. Your eCommerce business’s success or failure may hinge on the decision you make when it comes to appointing a third-party logistics warehouse. Customers are more likely to buy from you again if you ship orders quickly and accurately.

What is a Warehouse

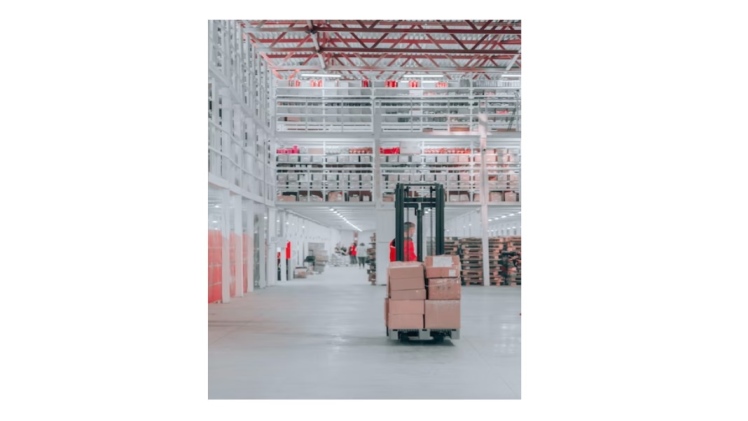

A warehouse is a facility where goods are stored for an indefinite period of time on behalf of retailers. A warehouse is a large structure or industrial space used to store products before they are shipped to customers.

Warehouses may house large containers, shelves, storage bins, and pallets, all of which hold products labeled with individual Stock Keeping Unit (SKU) numbers, in addition to machinery like forklifts.

Large-scale, bulk orders from other businesses are the primary focus of the companies that contract with warehouse providers. Some online retailers keep their surplus stock in warehouses they own and operate themselves, while others rent warehouse space as needed.

Warehouse space for rent is often the most cost-effective option for small and medium-sized retailers fulfilling online orders, though this does vary by location and the terms of the lease.

Without their own warehouse, smaller retailers and start-ups may opt for cheaper, less permanent storage options like local storage units to house their goods. This allows them to store the necessary items in a more convenient and economical location close to their home.

What Exactly Is A Fulfillment Center?

When a customer places an order through an online store (also known as direct-to-consumer fulfillment) or a business-to-retail fulfillment order (also known as wholesale fulfillment), the seller (or the company the seller hires to outsource their fulfillment) ships the product to the customer from a fulfillment center.

The scale and size of these facilities tend to exceed those of the typical warehouse that a single company might own or rent. To put it simply, a fulfillment center is a warehouse that stores a seller’s inventory and fulfills customer and/or wholesaler orders.

What Are The Primary Differences Between Warehouses And Fulfillment Centers?

The terms “warehouse” and “fulfillment center” are often used interchangeably, but there are significant differences between the two when it comes to the roles they play in getting products to customers.

A warehouse’s primary function is to store goods, but a fulfillment center’s is to improve the shopping and delivery experience for customers. Because the seller’s stock is kept at a 3PL fulfillment center in close proximity to the buyer, shipping times and costs can be kept to a minimum.

According to research, 60% of 3PLs now fulfill orders in fewer than ninety minutes, up from 53 percent in the previous year, in order to keep up with rising client expectations. Furthermore, yearly order volume growth is strongly correlated with order fulfillment speed. Rising from 22% last year, nearly a third now complete purchases in under 30 minutes.

Short-Term Versus Long-Term Storage

Although a fulfillment center may include a warehouse where a seller’s inventory is stored, its primary function is to streamline the processes that occur between the time an order is placed and the time it is delivered to a customer’s home or place of business.

No goods should spend more than 30 days in a distribution center. Most third-party logistics providers (3PLs) will charge more for warehousing services if inventory needs to be kept in a fulfillment center for an extended period of time.

Frequent and consistent communication between the seller and the 3PL regarding stock levels is preferred. The seller must have an adequate inventory of their products, taking the 3PL fulfillment center’s order volume into mind to guarantee timely delivery to customers.

The two terms are sometimes used interchangeably. However, there is a huge gap between the necessity of a simple warehouse and the option to use entire fulfillment solutions via a fulfillment center. The best service for a given seller depends on their specific requirements.

If storage is required for an extended period of time or if the business is still handling some aspects of fulfillment in-house, a warehousing service that focuses solely on storage could be beneficial.

If a seller has a high volume of orders that need to be processed quickly, outsourcing these functions to a third-party logistics provider (or “3PL”) may be the best way to expand the business. All of these concerns can be addressed with the assistance of a reliable fulfillment partner.