TIG welding machine is a popular welding method in industrial and automotive applications. TIG welding is known for its high-quality welds, free of defects such as porosity, cracking, and spatter.

Therefore, a Tig welding machine is essential for welders specializing in TIG welding. This article will explore the features of a TIG welding machine and its operations.

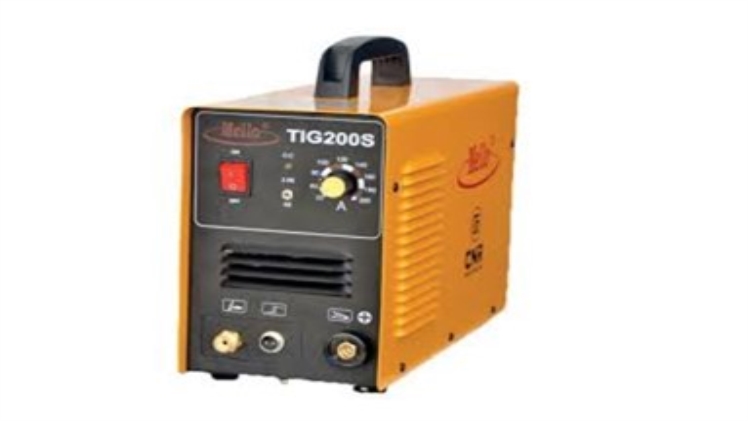

It has several components, like a power source, welding torch, and shielding gas system. The power source provides the current required for the welding process. The welding torch holds the tungsten electrode and delivers shielding gas to the weld zone. The shielding gas system protects the weld from atmospheric contamination and oxidation.

Produce a stable arc.

One of the critical features of a TIG machine is its ability to produce a stable arc. This arc is made by the high-frequency current produced by the power source, which ionizes the air around the tungsten electrode. The ionized air allows current to flow. Thus, resulting in arc melts of the base metal and filler material.

Control heat input into the weld.

TIG machine can control heat input into the weld. The heat input is controlled by adjusting the amperage and welding speed. The amperage controls current flow through the weld, while the welding speed controls the time weld is exposed to heat. Maintaining heat input is crucial for producing high-quality welds and preventing overheating, which can lead to distortion and warping.

It also has a variety of settings that are adjusted to suit different materials and thicknesses. These settings include the polarity of the welding current, the type and flow rate of the shielding gas, and also the type and size of the tungsten electrode.

How TIG Welding Machine Works.

The TIG welding process starts by preparing a base metal and filler material. The base metal is cleaned and prepared by removing dirt, rust, or paint. Then filler material is selected based on the material welded and the required strength of the weld.

Then, the next is to set up the TIG welding machine. This involves selecting the appropriate settings for the material and thickness. Then tungsten electrode is inserted into the welding torch, and the shielding gas is turned on.

Begin the welding process.

Once the TIG welding machine is set up, the welding process can begin. The welding torches over the base metal, and the arc is initiated by striking the tungsten electrode against the base metal. Therefore, the welder feeds filler material into the weld zone, melting it with the arc’s heat. The welder moves the welding torch along a joint, adding filler material until the weld is complete.

They are applied in metals and alloys as compared to other processes.

TIG welding machines can be applied in stainless steel, aluminum, nickel alloys, and other metals. It does not produce smoke unless the welded materials contain contaminants like paint, oil, zinc, etc. Therefore, materials should be clean.

Conclusion

TIG welding is a popular method known for its high-quality welds and precision. Therefore, a TIG welding machine is essential for welders specializing in TIG welding. Its features enable it to produce stable arcs, control heat input, and adjust to different materials and thicknesses.

By understanding how the TIG welding machine works, the welders can produce high-quality welds free of defects and meet the required specifications.